Fasteners and Machining: Enhancing Toughness and Performance in Production

Fasteners and Machining: Enhancing Toughness and Performance in Production

Blog Article

Navigating the World of Fasteners and Machining: Strategies for Accuracy and Rate

In the detailed world of bolts and machining, the quest for accuracy and rate is a perpetual difficulty that requires careful focus to detail and calculated planning. From comprehending the diverse selection of fastener types to picking optimum products that can hold up against strenuous needs, each action in the procedure plays a crucial role in attaining the wanted end result.

Understanding Fastener Kind

When selecting fasteners for a project, comprehending the various kinds available is essential for making certain optimum performance and dependability. Fasteners come in a large range of kinds, each created for specific applications and demands. Bolts are utilized with nuts to hold materials together, while screws are versatile fasteners that can be made use of with or without a nut, depending on the application. Nuts, on the other hand, are inside threaded bolts that friend with bolts or screws, providing a safe and secure hold. Washing machines are important for dispersing the lots of the fastener and avoiding damages to the product being secured. Furthermore, rivets are permanent bolts that are ideal for applications where disassembly is not needed. Recognizing the distinctions in between these bolt kinds is vital for selecting the right one for the task, making certain that the link is strong, long lasting, and reputable. By picking the ideal fastener type, you can optimize the performance and longevity of your project - Fasteners and Machining.

Selecting the Right Products

Recognizing the importance of selecting the appropriate products is paramount in guaranteeing the ideal efficiency and integrity of the picked fastener types reviewed formerly. When it involves fasteners and machining applications, the material option plays a crucial function in establishing the general strength, resilience, rust resistance, and compatibility with the designated atmosphere. Different materials offer differing homes that can substantially affect the performance of the bolts.

Typical products utilized for fasteners consist of steel, stainless steel, titanium, brass, and light weight aluminum, each having its distinct staminas and weak points. Steel is renowned for its high stamina and resilience, making it suitable for a large range of applications. Selecting the appropriate product includes taking into consideration variables such as stamina demands, ecological conditions, and spending plan constraints to make sure the desired performance and durability of the fasteners.

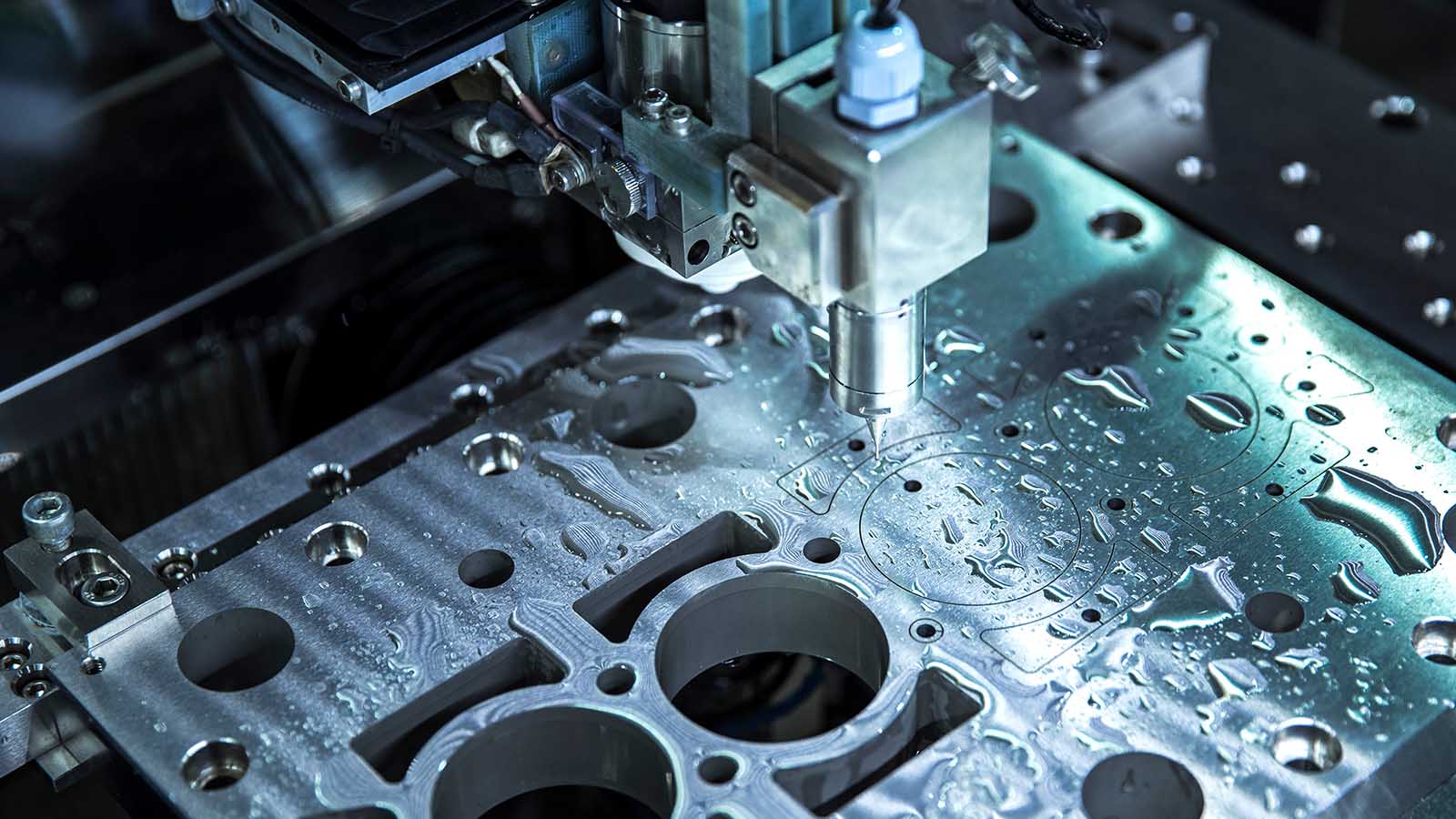

Accuracy Machining Techniques

In addition to CNC machining, other accuracy strategies like grinding, turning, milling, and drilling play vital roles in bolt manufacturing. Grinding helps achieve great surface finishes and tight dimensional resistances, while turning is often utilized to create round parts with exact sizes. Milling and exploration operations are important for forming and developing holes in bolts, guaranteeing they meet specific requirements and feature properly.

Enhancing Speed and Effectiveness

To optimize bolt production processes, it is vital to improve procedures and execute efficient approaches that match accuracy machining methods. Automated systems can take care of repeated tasks with precision and rate, permitting employees to focus on more facility and value-added activities. By integrating these methods, manufacturers can achieve a balance in between rate and accuracy, inevitably enhancing their competitive side in the fastener industry.

Quality Control Steps

Applying rigorous high quality control steps is crucial in making certain the dependability and uniformity of fastener products in the production process. Quality control procedures encompass numerous stages, beginning from the choice of raw products to the last assessment of the finished bolts. One fundamental aspect of quality control is performing extensive product evaluations to validate conformity with specifications. This involves examining variables such as material composition, strength, and toughness to assure that the bolts fulfill sector requirements. Additionally, checking the machining processes is important to copyright dimensional precision and surface area coating high news quality. Using sophisticated technology, such as computerized evaluation systems and accuracy measuring devices, can enhance the accuracy and performance of quality assurance procedures.

Regular calibration of devices and equipment is critical to keep uniformity in production and guarantee that bolts fulfill the necessary tolerances. Implementing strict methods for identifying and dealing with non-conformities or defects is essential in stopping substandard items from entering the marketplace. By establishing an extensive top quality control structure, producers can support the online reputation of their brand name and provide fasteners that satisfy the greatest standards of performance and sturdiness.

Verdict

In the intricate world of bolts and machining, the mission for accuracy and speed is a continuous obstacle that demands meticulous attention to information and strategic preparation. When it comes to fasteners and machining applications, the material click this option plays an essential duty in figuring out the total stamina, sturdiness, deterioration resistance, and compatibility with the designated environment. Accuracy machining entails different advanced methods that make certain the limited tolerances and specs needed for fasteners.In enhancement to CNC machining, various other accuracy techniques like grinding, transforming, milling, and drilling play crucial functions in fastener manufacturing.To enhance bolt production procedures, it is vital to enhance procedures and carry out reliable approaches that complement accuracy machining strategies.

Report this page